|

| January 19, 2021 | Volume 17 Issue 03 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

How to keep drones flying -- and on course -- when a motor fails

Robotics researchers at the University of Zurich in Switzerland recently demonstrated how onboard cameras can be used to keep damaged quadcopters in the air and flying stably -- even without GPS.

As anxious passengers are often reassured, commercial aircrafts can easily continue to fly even if one of the engines stops working. But for drones with four propellers -- also known as quadcopters -- the failure of one motor is a bigger problem.

With only three rotors working, the drone loses stability and inevitably crashes unless an emergency control strategy sets in.

Researchers at the University of Zurich and the Delft University of Technology in the Netherlands have now found a solution to this problem: They have demonstrated that information from onboard cameras can be used to stabilize the drone and keep it flying autonomously after one rotor suddenly gives out.

"When one rotor fails, the drone begins to spin on itself like a ballerina," says Davide Scaramuzza, head of the Robotics and Perception Group at UZH and of the Rescue Robotics grand challenge at NCCR Robotics, which funded the research. "This high-speed rotational motion causes standard controllers to fail -- unless the drone has access to very accurate position measurements."

In other words, once it starts spinning, the drone is no longer able to estimate its position in space -- and eventually crashes.

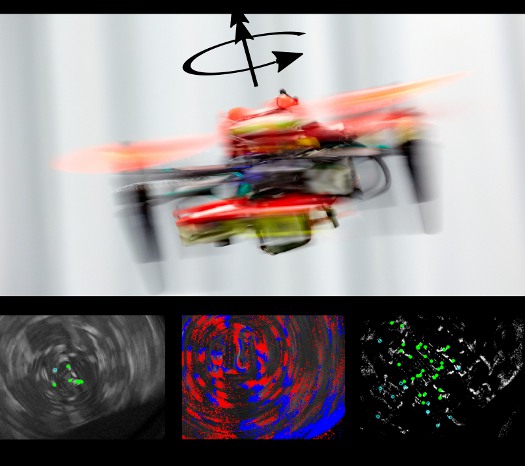

When one rotor fails, the drone begins to spin on itself like a ballerina. The algorithms combine the information from the sensors to track the quadrotor's position in the environment. (Image: UZH)

One way to solve this problem is to provide the drone with a reference position through GPS. However, there are many places where GPS signals are unavailable.

In their study, the researchers solved this issue for the first time without relying on GPS, instead using visual information from different types of onboard cameras.

VIDEO: Autonomous quadrotor flight despite rotor failure with onboard vision sensors.

The researchers equipped their quadcopters with two types of cameras: standard ones, which record images several times per second at a fixed rate, and event cameras, which are based on independent pixels that are only activated when they detect a change in the light that reaches them.

The research team developed algorithms that combine information from the two sensors and use it to track the quadrotor's position relative to its surroundings. This enables the onboard computer to control the drone as it flies -- and spins -- with only three rotors.

The researchers found that both types of cameras perform well in normal light conditions. "When illumination decreases, however, standard cameras begin to experience motion blur that, ultimately, disorients the drone and crashes it," says first author Sihao Sun (a postdoc in Scaramuzza's lab), whereas event cameras also work well in very low light."

The researchers think the problem addressed by this study is a very relevant one, because quadcopters are becoming widespread and rotor failure may cause accidents. Their hope is that their work can improve quadrotor flight safety in all areas, including where a GPS signal is weak or absent. They have published their work in IEEE Robotics and Automation Letters, January 2021.

Source: University of Zurich

Published January 2021

Rate this article

View our terms of use and privacy policy